AI implementation in manufacturing is a game-changer, offering increased productivity, cost efficiency, reduced downtime, and enhanced quality control. With predictive analytics and intelligent automation, AI processes large volumes of data to deliver insights that traditional methods cannot match.

These insights make way for smarter processes, ensuring a more agile, responsive, and profitable manufacturing environment.

How is Salesforce Einstein AI Shaping the Future of Manufacturing?

AI algorithms in manufacturing analyze historical and real-time data to:

- Predict equipment failures before they occur, enabling proactive maintenance

- Identify potential supply chain disruptions to prevent bottlenecks

- Adjust production schedules dynamically based on market trends or demand fluctuations

Salesforce Einstein AI delivers intelligent automation, predictive insights, and data-driven decision-making within manufacturing environments. By analyzing vast datasets, Einstein AI empowers manufacturers to enhance operational efficiency, optimize resources, and drive profitability.

This blog explores how Einstein AI is revolutionizing manufacturing by highlighting five key use cases that maximize efficiency and streamline operations.

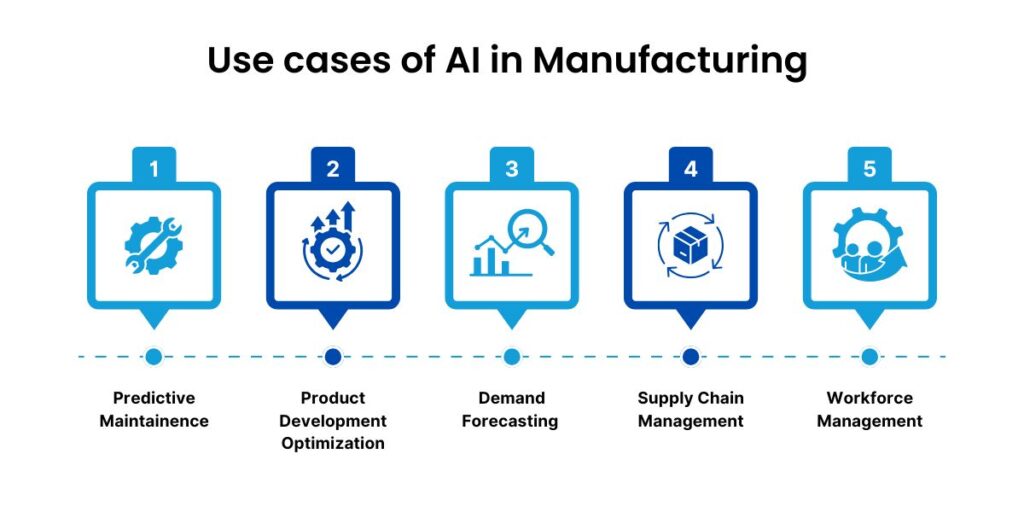

5 Impactful Use Cases of AI in Manufacturing

1. Predictive Maintenance to Prevent Equipment Failures

Equipment failures can severely disrupt manufacturing operations, leading to unplanned downtime and significant financial losses.

Einstein AI leverages its advanced predictive analytics to analyze sensor data, maintenance logs, environmental factors, operational insights, and machine usage patterns in real time. By identifying early warning signs of potential equipment failures, it enables manufacturers to take timely action. Einstein Generative AI provides tailored recommendations, such as proactive maintenance schedules or even equipment replacement suggestions for high-risk assets. This data-driven, proactive approach minimizes downtime, lowers emergency repair costs, and ensures optimal performance for manufacturers.

Learn more on how AI saves cost and prevents downtime in the manufacturing industry

2. Product Development Optimization for Market Success

Unplanned development stages, such as poor product design, missteps in pricing, or misaligned market launch strategies, often lead to product failures and significant financial losses in manufacturing.

AI helps streamline product development by analyzing data from IoT devices, consumer behavior, customer feedback, material development, and market demand trends. Using predictive analytics, AI turns this data into actionable insights that reduce risks, predict trends, and optimize the entire product lifecycle. From ideation to prototyping and market launch, AI improves decision-making, enhances product design, and ensures that products align with consumer needs, delivering maximum value.

3. Demand Forecasting to Meet Market Needs

Market volatility, fluctuating raw material prices, delayed shipments, and regional demand spikes are persistent challenges for the manufacturing industry. These factors complicate demand forecasting, often leading to overproduction or stockouts.

AI transforms this process by analyzing a wide range of data—seasonal trends, customer purchase behavior, and external market factors like economic indicators. By uncovering hidden patterns that traditional systems might miss, AI enhances forecast accuracy, enabling manufacturers to align production with actual demand. This proactive approach helps minimize disruptions, optimize inventory, and ensure a more responsive and efficient supply chain.

4. Supply Chain Management to Improve Resilience

Supply chain problems like material shortages, high cost of production, changing customer behavior, or geopolitical disruptions in manufacturing can lead to delayed shipments and harm a brand’s reputation.

Currently, 41% of manufacturers use AI-based applications to gather and manage supply chain data.

AI-powered predictive analytics in supply chain management collects and analyzes data from sales, inventory, and suppliers. It processes this data to uncover key insights, such as order volumes, traffic patterns, and weather conditions. AI uses these insights to predict potential disruptions and recommend actions. For example, it helps adjust production schedules, optimize inventory, and reroute shipments to minimize delays. This enables more efficient decision-making and smoother operations.

5. Workforce Management to Enhance Productivity

Workforce management in manufacturing faces challenges like labor shortages, skill gaps, and staff misallocation.

Einstein AI integrates with manufacturing ERP systems to analyze real-time workforce and production data. It predicts workforce demands, optimizes shift schedules, and evaluates employee performance. This helps prevent under/overstaffing and reduces unnecessary costs. AI also identifies skill gaps within the workforce and recommends personalized training resources. The result is a more efficient, skilled, and well-equipped workforce.

Following Up

Implementing AI in the manufacturing industry offers significant benefits, but the path to adoption comes with challenges. One of the main obstacles is data quality, as manufacturers often handle large, incomplete, or inaccurate datasets, which hinder the effectiveness of AI models. Einstein transforms data management by automating data cleansing and eliminating duplicates, ensuring higher-quality data for analysis.

Know more: Beyond Predictions – AI Driving Real-World Impact Across Industries

Another challenge is integrating AI with existing systems and technologies, coupled with concerns around adoption and change management. AI addresses this by simplifying integration and automating data workflows, reducing system compatibility issues.

The biggest hurdle, however, is identifying where AI can truly add value. Without a proper assessment, manufacturers may struggle to justify the investment and miss out on AI’s full potential. Einstein helps by analyzing massive datasets to uncover patterns, enabling smarter decision-making and driving greater operational efficiencies.

AblyPro addresses AI implementation challenges with our 3A’s approach: Assess, Analyze, Act. We first identify the need for AI and key business areas where AI implementation will be effective. Next, we cleanse and prepare data to build predictive models that drive actionable insights. Finally, we help act on AI-powered recommendations, enabling data-driven decisions, optimized operations, and tangible results.

Explore the 3A’s approach in detail here.

Want to learn more about AI implementation in manufacturing? Chat with us!

Author

AVP, AblyPro

Murali is the AVP – Certinia at AblyPro with 12+ years of experience in handling complex Certinia and Salesforce applications, implementations, configurations, and customizations. At AblyPro, he has been the pillar of all the Certinia PSA and ERP project deliverables, ranging from design to implementation, project management, and resource management. With years of practical knowledge and expertise in this industry, Murali supports the sales team in strategizing customer solutions to meet the actual business needs of the clients. Murali is a dynamic and experienced professional with multiple Certinia and Salesforce certifications, helping businesses to technically strive in this ever-changing landscape.